If you currently own a waste processing business, investing in pyrolysis equipment from a globally renowned manufacturer (пиролизные оборудование от всемирно известного производителя) is almost guaranteed to be a wise choice. The main benefits of pyrolysis plants are that they produce zero toxic emissions during operation and they can convert all sources of rubbish into valuable commodities. Read on to find out about some of the many waste material categories that pyrolysis technology can process.

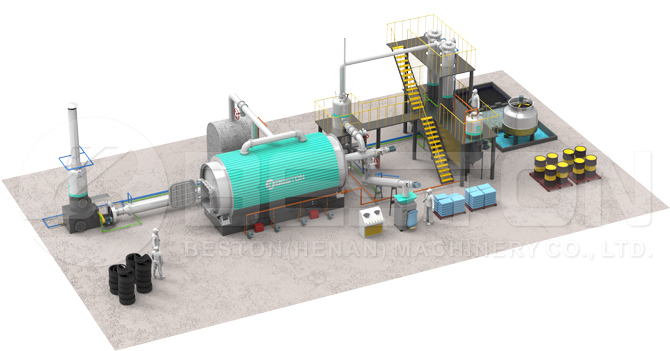

Tire (Rubber) Waste

Arguably one of the biggest benefits of pyrolysis plants is that they can turn scrap tires into fuel oil, steel wire, carbon black and combustible gas – all valuable products – via a zero pollution process. Think about how much damage to the environment waste tires do when they buried in landfill sites. Did you know that a typical tire takes between 50 and 80 years to decompose? With a rubber pyrolysis machine , that tire could be turned into fuel (пиролиз шины в топливо) for industry, generating healthy profits for a waste processing business. For reference, 1000kg (1 ton) of tires can contain up to 450kg of tire oil.

Plastic Waste

Now let’s think about plastic waste. Plastic items can take over 800 years to decompose in landfills. And, when plastic waste is dumped into the world’s oceans, it can cause great damage to fragile ecosystems in the water. We have all see those disturbing images of dead whales and dolphins whose insides are full of plastic waste. Further conventional waste disposal methods, such as incineration, also cause a lot of damage to the environment. When plastic is burned, it produces lots of toxic fumes.

The goods news is that with a pyrolysis plant, your waste processing business can turn all of the incoming plastic waste into salable commodities without polluting the environment. Fuel oils of different viscosities can be recovered from plastic items via pyrolysis. These oils are easy to sell in the global market space.

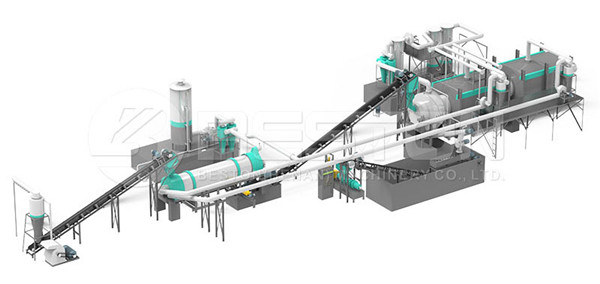

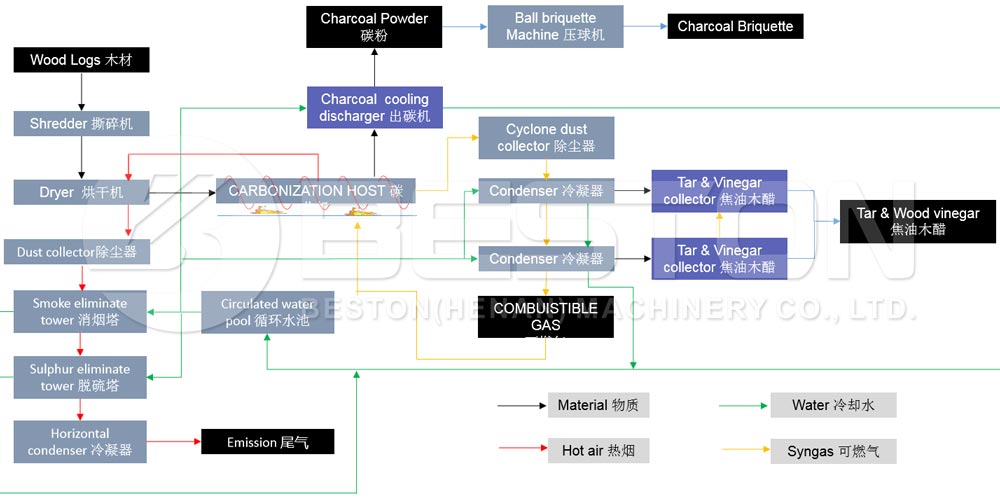

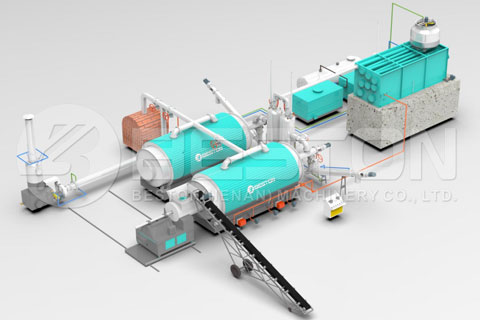

Biomass Waste

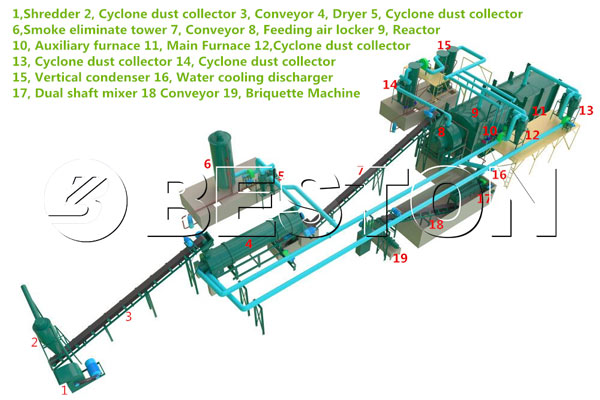

Biomass waste, such as coconut shells, palm kernel shells, sawdust, straw, wood, bamboo, agricultural waste, risk husks and more, can all be converted into bio charcoal with a pyrolysis plant. Via carbonization, all types of biomass waste can be transformed into high carbon biochar. There are many applications for biochar. For example, it can be reshaped into fuel briquette and used as barbeque fuel. In fact, biochar is perfectly suited as a cooking fuel as it emits little smoke when burning. Biochar also makes a great soil additive, improving root aeration and crop yields. In the wastewater treatment industry, biochar is particularly valuable as it can be converted into activated carbon and used as a purifying agent.

In conclusion, the primary benefit of a pyrolysis plant is that it can recover valuable resources from all types of waste without outputting any pollution into the environment. Modern plants also have the added advantage of having very low running costs due to advanced energy efficiency designs, ensuring waste recycling businesses can generate large profits. So, what are you waiting for? Why not invest in a pyrolysis plant for your business today? Consider this supplier:www.bgenvirontech.uz