Charcoal in simple terms is that black residue that remains when wood or other biomass is heated in the absence of oxygen or in an insufficient amount of oxygen. It is chiefly made of carbon although other elements and substances may be present as impurities.

Charcoal has various uses among which is for heating purpose, as an adsorption medium used in the removal of harmful substances from manufacturing processes like in the production of some wines. It can also be used in the production of various fuels like syngas which is a mixture of carbon monoxide carbon dioxide and hydrogen. Charcoal is also used in the production of gun powder where it is mixed with sulphur.

In the production of charcoal, it is important that air is excluded or prevented from entering the heating compartment during heating as this would case the biomass to turn to ash.

Most of the biochar machines for sale are designed to ensure that proper heating of the biomass occurs while air or oxygen is prevented from entering the heating chamber. The machines are usually supplied with biomass in the form of pellets or sawdust and it is compressed into lumps.

These lumps are the heated to between 300and 700 depending on the quality of the charcoal desired, after heating , the charcoal are then pressed to custom shaped outlet and later cut to size.

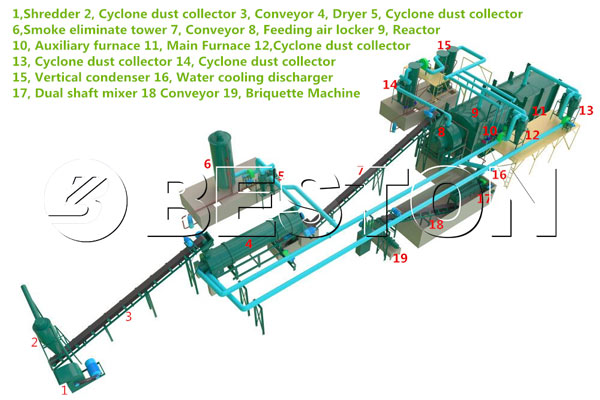

CONSTITUTION OF A COMPLETE CHARCOAL MACHINE

The charcoal making machine is basically made up of the feed, the powerhouse and the heating section.

·The powerhouse: this is the part of the charcoal making machine that supplies the energy for operation. It is mostly an electric motor that powers the propeller and controls the movement of the biomass from the feed to the collection area. The powerhouse also supplies the electrical power for the heating of the heating ring in the heating section.

·The feed: the consists of a funnel-like structure which collect the biomass and passes it into the heating section of the sawdust making machine through the propeller. The propeller is basically a helix coil around a steel cone which facilitates the movement of the biomass from the feed to the forming ring inside the heating section. The machine produced by Henan Beston Machinery uses the sealed feeding system to make sure there’s no ash and dust during the working process.

·The heating section. This is where the biomass is heated to form charcoal. It consists of the heating ring and the forming cylinder. The heating ring is placed around the forming cylinder and turn on during operation; this causes the forming cylinder to heat up along with its content. The forming cylinder possesses two exits, one to give out the charcoal after it has been produced ad another to release the constituents of the liquid of the biomass expelled during the production of the charcoal.

PROBLEMS OF THE CHARCOAL HEATING MACHINE

Some of the problems of the charcoal heating machine are: https://www.bestongroup.com/biomass-pyrolysis-plant/.

·Overheating of the heating ring: overheating of the hearing ring is when the heating ring in the heating section of the charcoal making machine overheats or heats beyond the desired temperature which can lead to production of charcoal with undesirable quality, excessive consumption of energy, waste of materials, inefficiency of machine and increased cost of operation. To prevent this, care must be taken to ensure that the heating ring is being operated at the recommended ratings or voltage.

·Charcoal fracture phenomenal: this is a situation whereby the produced charcoal fractures after production which can make the charcoal fragile and break easily. A number of things contribute to this phenomenal among these are: excessive heating of the forming cylinder as a result of overheating heating coils which makes the carbonation process occur too fast; material type – different biomass require different temperature for carbonation and if the wrong temperature is set, it can lead to fracturing of the final charcoal produce. Also, the nature of the biomass before it is fed to the feeding chamber is important, biomass should be properly dried and emptied of their moisture content to prevent steam buildup during the heating process.

Click it if you want to know the charcoal making machine price.