An egg carton machine is a type of pulp molding machine that turns recycled paper into egg cartons. Egg cartons or egg boxes offer more protection to eggs than trays, so they are in high demand in many countries. Many experienced pulp molding equipment manufacturers have added egg carton machines to their production lines, so anyone who wants to start a plant producing packaging for egg suppliers should find it easy to source top-quality machines.

Types of Egg Carton Manufacturing Machines

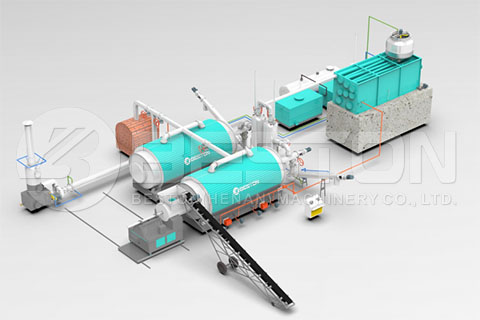

Egg carton machines are available in three different designs: manual, semi-automatic, and fully automatic. The average output of a manual machine is around 2000 pieces per hour. Companies that have access to a cheap labor force can reduce their investment costs in machinery by opting for a manual machine and using natural drying lines. Companies that want high-efficiency production, however, need to consider investing in egg box making machine that has semi-automatic or fully automatic drying systems. A top of the range fully automatic egg box making machine will be capable of producing 6000 pieces per hour continuously.

Key Benefits of Paper Egg Carton Machines

1. Cost-effective packaging business opportunity.

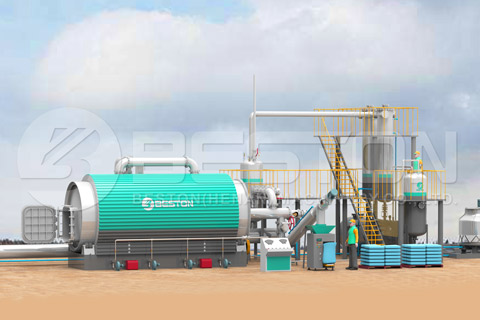

Egg tray machines manufactured by Beston Machinery have low operating costs and high output rates. The raw materials needed to feed the machines are cheap to source, and the end products are easily sold for a profitable markup in the packaging industry. Furthermore, the initial investment costs are fairly reasonable, especially for those looking to buy small-scale manual machines: https://www.bestongroup.com/egg-tray-making-machine/manual/.

2. An eco-friendly production line.

Paper egg tray making machine in India turn paper that would otherwise be disposed of in landfill sites into useful products for the food industry. When the machines are powered by a renewable power source, they are pollution-free.

3. End products have a wide market.

Recent market surveys have found that plastic packaging usage is decreasing in many countries around the world with some countries going as far as to ban plastic packaging. This means there is a wide market for pulp molded packaging, like egg cartons, produced from recycled paper.

An egg carton machine has four key systems: the pulping system, the molding system, the drying system, and the packaging system. Before you invest in any machinery for your factory, it’s important that you learn more about the working processes of pulp moulding machine in india. You will then know how to set up an effective production line and workforce in your facility to run the best recyclable packaging business. Click here if you want to learn more info about how to make egg tray from waste paper.

Choosing A Manufacture

The best manufacturers have professional designers, engineers, and after-sales teams ready to go above and beyond when it comes to helping you start your own egg carton manufacturing business. They can send teams of experts to your factory to help assemble and commission your machines. Furthermore, they can provide your workforce with operational training and machine maintenance advice. When you buy a high-quality machine, the risk of costly malfunctions decreases greatly. You ideally want to buy equipment for your egg tray making machine China from a supplier that has at least a decade of experience in the industry.