In an era dominated by environmental concerns and climate change mitigation, the utilization of charcoal making machines has emerged as a potent tool for carbon sequestration and the generation of carbon credits. This remarkable synergy between technology and sustainability underscores a path forward in the global effort to combat carbon emissions and their adverse effects on our planet.

Carbon Sequestration with Charcoal Making Machines

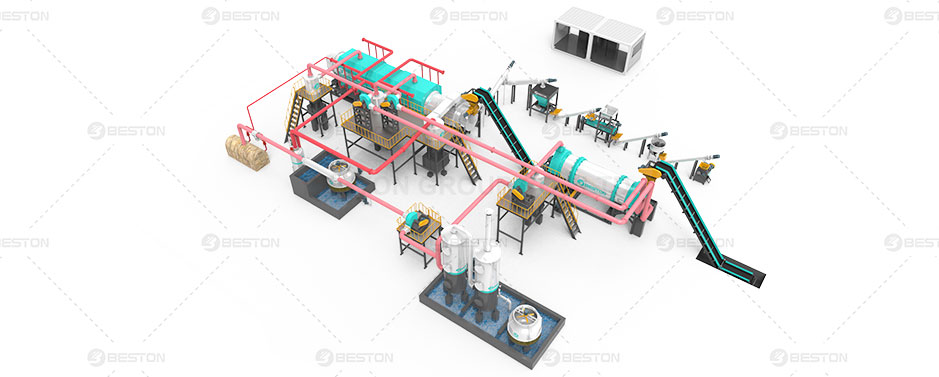

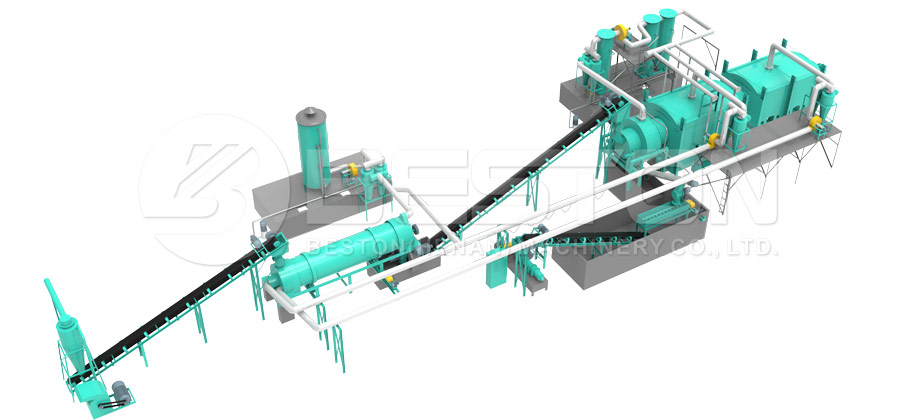

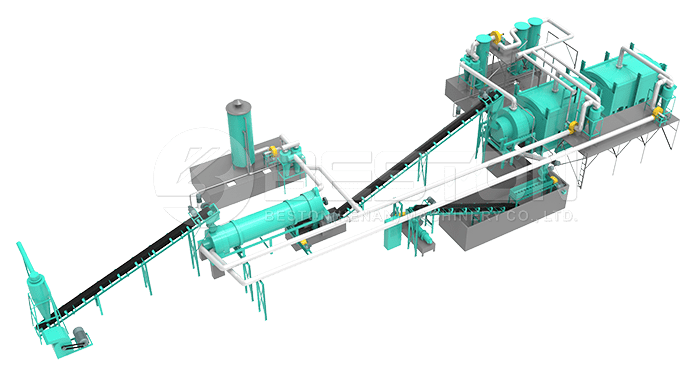

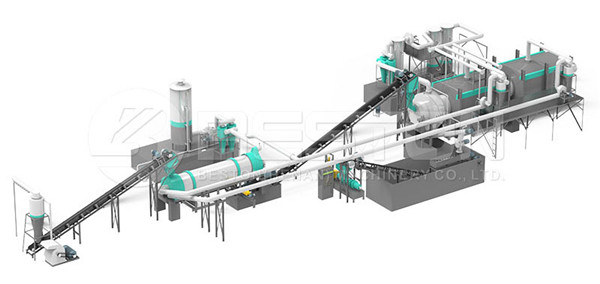

Carbon sequestration, the process of capturing and storing carbon dioxide (CO2) from the atmosphere, is essential in the battle against climate change. Charcoal making machine, primarily designed for the conversion of biomass into charcoal, have assumed a pivotal role in this endeavor. These machines employ a high-temperature pyrolysis process to transform organic materials such as wood, agricultural residues, and coconut shells into biochar, a stable form of carbon that can be locked away in the soil for centuries.

The biochar produced by charcoal making machines acts as a carbon sink, effectively sequestering carbon that would otherwise contribute to the greenhouse effect. When incorporated into agricultural soils, biochar enhances soil fertility, improves water retention, and boosts crop yields. Moreover, the carbon sequestered within the biochar remains locked away, reducing atmospheric CO2 concentrations and mitigating climate change.

Harnessing Carbon Credits through Biochar

One of the most compelling aspects of utilizing charcoal making machines for carbon sequestration is its potential to generate carbon credits. Carbon credits, also known as carbon offsets, represent a tradable commodity that quantifies the reduction of greenhouse gas emissions. By sequestering carbon in the form of biochar, organizations and individuals can accrue carbon credits, which can then be sold or traded in carbon markets. This financial incentive not only promotes the adoption of carbonization equipment but also rewards those who actively contribute to carbon reduction efforts.

The carbon credits generated through charcoal making machines hold immense value in the context of international climate agreements such as the Kyoto Protocol and the Paris Agreement. These agreements mandate specific emission reduction targets for participating nations. By utilizing biochar from biochar production equipment as a carbon sequestration tool, countries can offset their emissions and meet their obligations under these global accords.

Beyond Agriculture: The Versatile Applications of Biochar

Furthermore, the application of charcoal making machines extends beyond carbon sequestration in agriculture. In the construction industry, for instance, the incorporation of biochar into concrete mixtures enhances structural integrity while reducing the carbon footprint of buildings. This innovative use of biochar aligns with sustainable construction practices, further amplifying the importance of carbonizaton machine in the broader context of carbon reduction.

Considerations for Effective Carbon Sequestration

It is worth noting that the adoption of charcoal making machines is not limited to large-scale industrial operations. Small-scale and community-based initiatives are also harnessing the power of these machines to sequester carbon, improve soil quality, and promote sustainable land management practices.

However, the successful deployment of wood charcoal machine for carbon sequestration and carbon credit generation requires careful planning and adherence to best practices. Factors such as feedstock selection, pyrolysis temperature, and post-processing techniques play a crucial role in maximizing the carbon sequestration potential of biochar. Additionally, the quantification and verification of carbon credits demand rigorous monitoring and reporting protocols to ensure transparency and credibility in carbon markets.