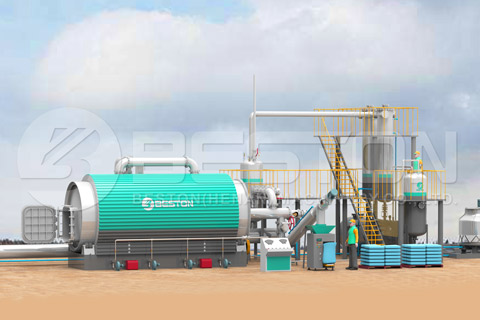

Over the last five years, Beston Machinery has designed commercial tire pyrolysis equipment for sale to cater to the flourishing demand on the need for tire pyrolysis worldwide. Waste tyre pyrolysis plant for sale then becomes the most effective way to reduce these scrap tires in a very economical way.

Key Advantages of Tire Pyrolysis Equipment for Sale

It is a relatively simple, inexpensive technology and environmental-friendly used in pyrolysis a wide variety of tire feedstocks. It plays a major role in environmental conservation since the tires which were traditionally disposed of in landfills are now very economic resources processed to produce an oil used as fuel. The greenhouse gases produce while burning tired are also reduced thus preserving the environment.

Tire pyrolysis equipment is also very profitable in that the oil produced is a major source of energy which has a significant potential to improve a country energy production thus reducing the dependence of imported power. Go on Beston Machinery to see more advantages.

The raw material for the plant is cheap and readily available since most people scrap tires are of less importance.

Apart from the oil produced, there is steel metal which is the by-product of tires. This diversification of the products increases your market thus increasing your profitability.

It is relatively rapid to implement tire pyrolysis equipment for a sale construction project. This ensures a rapid return on your investments. With modern technology in the pyrolysis plants, tire waste management has become an economic activity thus return on your investment is assured.

Tire pyrolysis plant for sale is available at relatively affordable prices. It is available whenever you want i.Note this plant has led to the creation of more new jobs to the youths through tire waste clean up which in turn improves their living conditions and boosting the public health in general.

The huge number of scrap tires is becoming an alarming environmental problem. Tire pyrolysis equipment for sale is available for this waste management purpose.

Tire pyrolysis is actually been encouraged as a way of reducing a large number of scrap tires all over the world. Burning tires directly in the open atmosphere has many negative effects hence a better and an economical way to dispose of these tires is by pyrolysis.

Applications for Tire Pyrolysis Equipment

The pyrolysis plant can be designed to suit the customer’s specific requirements. This is possible with the selection of a good engineering company with adequate expertise in the entire making of the pyrolysis plant. Control systems can be designed to be automated so that the plant can be manned while workers are away from the kiln itself. Consider buying a mobile tire pyrolysis equipment.

A good pyrolysis plant should be designed to operate throughout the week and seven days a week. This ensures maximum production. The carbon black is then directed to the ground and bagging system where it is parked readily for sale. The steel is cooled by cool steam before they are compacted into stable states then transported to the steel recycling companies. The gases produced off the kiln is regained through condenser systems. This ensures these gases are not released to the environment since most of these gases are harmful to the environment in general.

Uses of a Tire Pyrolysis Plant for Sale

Tire pyrolysis process is done by a system of machines. Roasting is done at lower temperatures in a reactor free from oxygen so that no actual burning. Before the actual pyrolysis is done the tires are places in shredding machines where they are broken into very tiny pieces. Note about a third of the weight of the tire is made of steel metal and carbon black so shredding is necessary to ensure better pyrolysis is achieved.

The tire is fundamental shredded and washed to remove any foreign objects attaching on the tires. The tiny tire chips, which are approximately three inches in size are transported to the recycling facility by conveyor belts. These tiny tire pieces are then directed directly into the rotary reactor. Click https://bestonturkey.com/tire-to-oil-machine/ to see different reactor with different capacity.

The heat in the reactor makes the rubber brittle in form thus separating from the steel. The melted rubber which now composes of oil and other gases is forced out of the reactor. This is the second stage. The last stage is processing the carbon black substance which is done by separating it from the reactor.