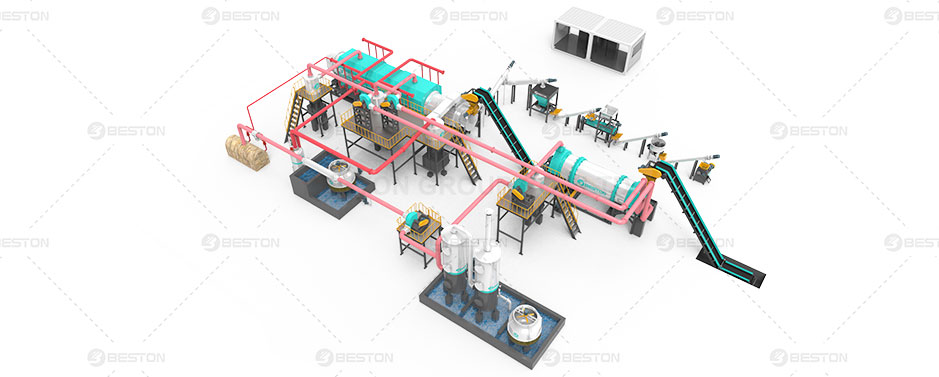

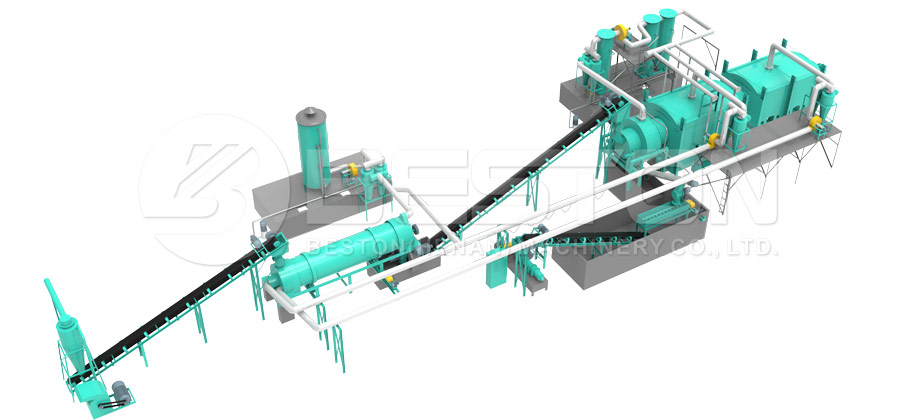

We mostly use plastic products. Unfortunately, plastic products pollute our environment. It is not easy to dispose of plastic waste. Fortunately, you can use a pyrolysis plant to convert these products into useful products. For instance, you can convert plastic waste into oil. A pyrolysis plant produces renewable energy sources.

Read on to learn why you should invest in a pyrolysis plant:

1. Protect Our Environment

Investing in a pyrolysis plant can help you protect the environment. You can use your pyrolysis plant to treat waste plastic. In addition, your plant will not pollute the environment since it does not produce harmful gases. The condensing system uses water. You will just recycle the water.

2. High Processing Capacity

A pyrolysis plant can process the raw materials throughout the day. You will not have to stop your pyrolysis plant during the day. You can, therefore, use your pyrolysis plant to process more raw materials during the day. In fact, your plant can run throughout the month. You will only stop your plant for regular checks and maintenance.

3. Convert Waste into Useful Products

If your business produces too much waste, do not just dispose of the waste. You can use your pyrolysis plant to convert your waste into useful products. The plant can even convert a wide range of materials into bio-oil. Luckily, the plant uses a lower temperature to turn waste into useful products. That is why the plant does not release too much carbon.

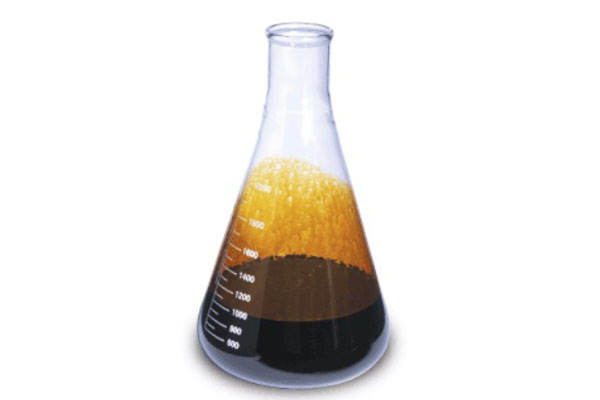

4. High Oil Yield

It is more efficient to use a small pyrolysis machine to produce oil. The oil gas cools fully in the condensing system. Investing in a pyrolysis plant can, therefore, increase your oil yield. It can even produce better yields. Increasing your oil yield increases your profits. If you want to produce oil and sell the oil, you should invest in this plant.

5. Get More Done Faster

It is easy to operate a pyrolysis plant. You do not need to hire an expert to help you operate your plant. You can use your plant to quickly convert waste materials into useful products. In addition, the machine can run throughout the day. You are more likely to get more done during the day.

6. It is Cheap to Use

It is expensive to purchase a pyrolysis plant. Once you purchase and install your plant, it can save you more money in the long term. It is cheap to use a pyrolysis plant in the long term. You do not need a lot of workers to operate your pyrolysis plant. The plant can even pay for itself since you can sell the useful products produced by your plant.

Investment guidance: https://bestonasia.com/pyrolysis-plant/is-pyrolysis-plant-profitable/.

7. It is easy to Operate

It is easy to operate a pyrolysis plant. If you choose the right manufacturer, your manufacturer can install your pyrolysis plant and train your workers to use your plant. The manufacturer might not charge you money to install and train your workers. Once your workers are properly trained, they can use your plant.

In Summary

Investing in a pyrolysis plant from Beston Group can help you protect the environment, increase your oil yield, and convert waste into useful products. You can sell these products to make some money. However, you need to purchase your pyrolysis plant from a reputable company.