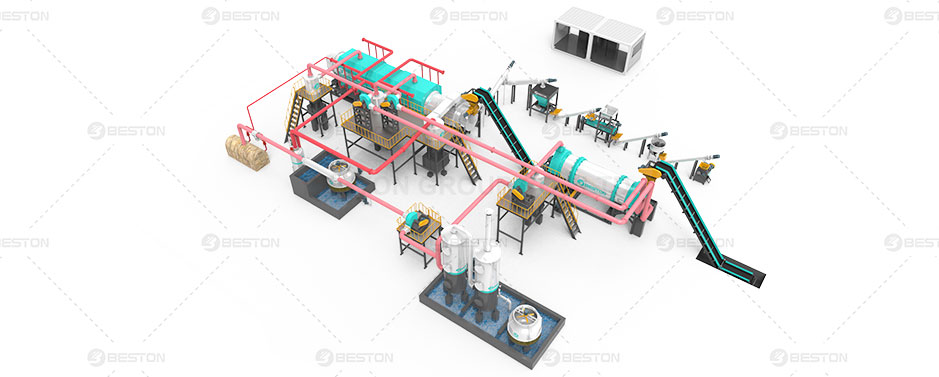

Are you thinking about investing in a tire pyrolysis plant and are interested in knowing whether it will be a profitable venture or not? If so, look no further. Everyone loves the certainty of knowing that they made a worthwhile purchase. If you plan to enter the tire pyrolysis business, you must know that there is so much to put into account to meet the primary goal- to make money. This is where research comes into play; therefore, you must be thorough. Compare prices since they vary depending on quality, the manufacturer, and materials used. The following are the benefits your business will experience after investing in a tyre pyrolysis plant:

Cheap Maintenance

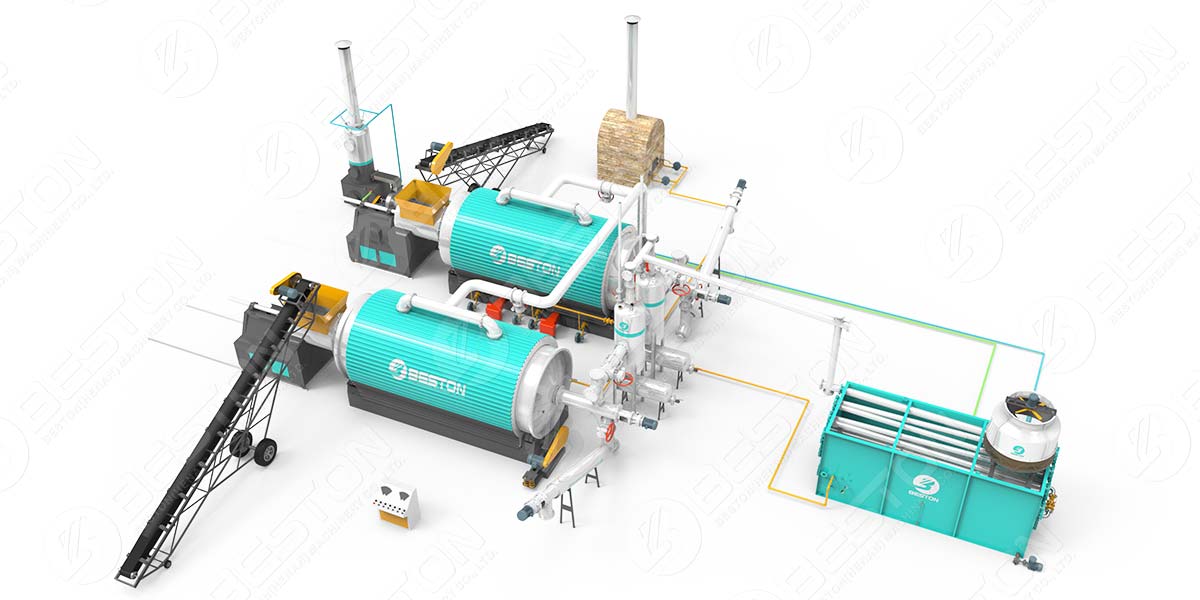

Who doesn’t love a machine that requires little to no maintenance? The tire pyrolysis plant is not one of those investments that will make you dig deeper into your pocket after purchase. However, to achieve this, you must choose the best manufacturer. There are many ways to find such, including online or through recommendations from family and friends. After finding the right manufacturer, have them install the pyrolysis plant properly. You have control over this because the chances are high that you won’t know whether the job has been done correctly. As a result, take time looking for a manufacturer who knows their way around this field and is experienced. Moreover, they can come in handy with their maintenance. Get pyrolysis plant cost here.

It Conserves the Environment

You have certainly seen how hard it is to get rid of old tires. Unlike before, the number of countries not accepting the latter has increased and won’t go down. Therefore, purchasing a tire pyrolysis plant is a niche for anyone looking for job opportunities. Old tires do not have any curb appeal and are not good for the environment. However, purchasing a pyrolysis plant will help process them.

Cheap Usage

As much as it costs a lot of money to buy and install, a tire pyrolysis plant is cheap to operate and maintain, as mentioned earlier. If you are lucky, the mobile pyrolysis plant manufacturer installing it may not charge you extra money. Also, this pyrolysis plant uses simple and cheap technology in processing old tires.

It Decreases Expenses

You would be surprised at how your monthly expenses would reduce after investing in a tire pyrolysis plant. This is because the tire pyrolysis plant consumes little energy, thus, reducing energy consumption greatly. As a business, this will be a plus because many businesses spend a lot of money catering to energy bills alone.

The above are the benefits of a small pyrolysis machine. Nothing should stop you from purchasing it since the benefits are amazing. The most you would spend is buying it since its maintenance and operation costs are lower. Therefore, buy the tire pyrolysis plant today and enjoy these benefits while converting old tires into useful products. Remember to opt for the manufacturer with the most recommendations, high ratings, a good reputation, and one with experience. Please do not compromise these things since they will cost you in no time. Also, inquire if they have after-sale services, for example, installation beforehand. This is because it will help you evade paying extra.