It’s possible that there is a charcoal kiln for sale that is going to meet your needs and be worth the price. However, there also may be some out there that are not good buys. If you want to learn what to spend money on, then take a look at the information here(carbonización de Beston).

Get familiar with a kiln by looking up what people have been saying about it in recent weeks. There are a lot of websites out there that can teach you about something like this through reviews(hornos metálicos para hacer carbón). When you’re looking for reviews, they need to be as detailed as possible instead of those that just say one or two sentences. That’s because the short reviews don’t tell you much and even if people give something a high score, without details you won’t really know why something is worth it.

Are you going to be able to save money on what you’re buying? Before you spend anything on this, you’re going to want to find out what a few companies want for the kilns that they have on sale. Never just buy one without looking it up and seeing what a few companies are charging. There will be some sellers out there that want a ridiculous amount for what they have so you have to be cautious. You shouldn’t spend more than what something is worth because when you do that, you don’t get anything extra with your purchase.

There may be a deal on kilns that’s going on around holidays or just when a store wants to give people deals to attract more business. It’s best to look up the company’s website or at least to find them on social media to see what they’re doing in the way of deals. Some companies will put out specials on a regular basis so it’s worth looking into this before you buy anything. If you ever are checking out on a site and see a place for a coupon code always stop what you’re doing to see if you can find a code to save money with through a search engine website(https://www.bestoneco.com/maquina-para-hacer-carbon-vegetal/).

It’s a good plan to look at used kilns if you don’t have a lot of money to spend on them. Sometimes sellers will have options that have been lightly used which are a much better deal than what you’d get if you were to buy one that hasn’t been used by anyone in the past. However, some sellers may try to get away with selling used kilns that don’t have a lot of life left in them so make sure you can return yours if you’re not happy with the shape it is in.

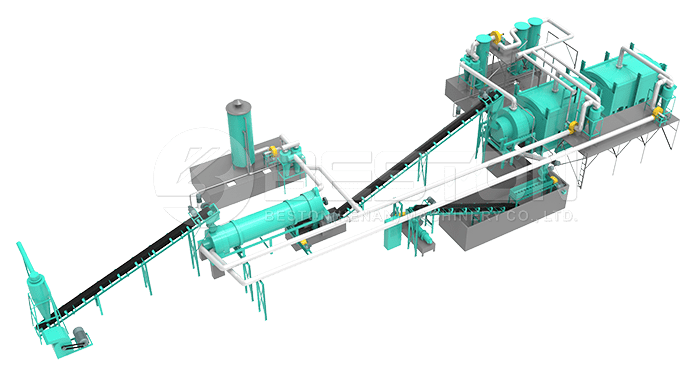

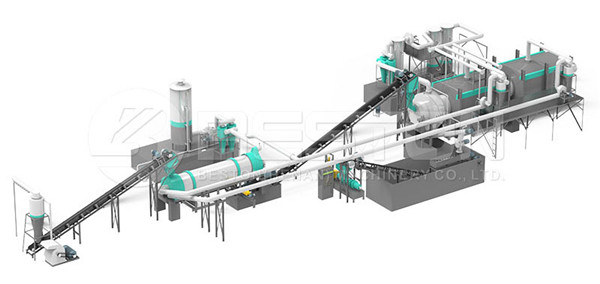

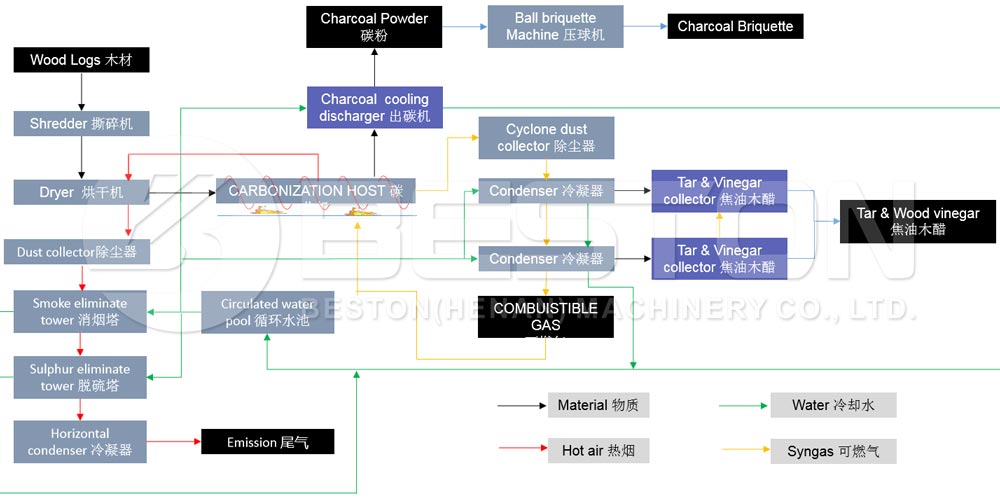

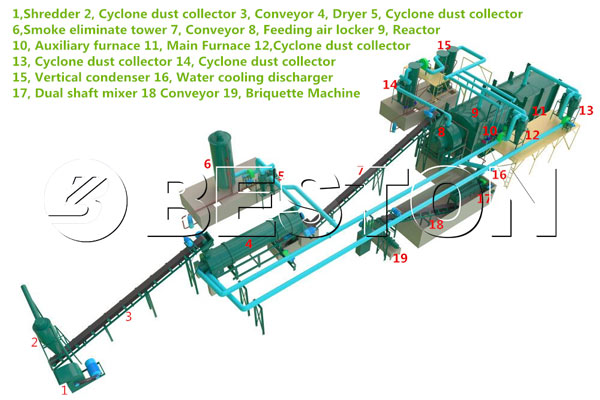

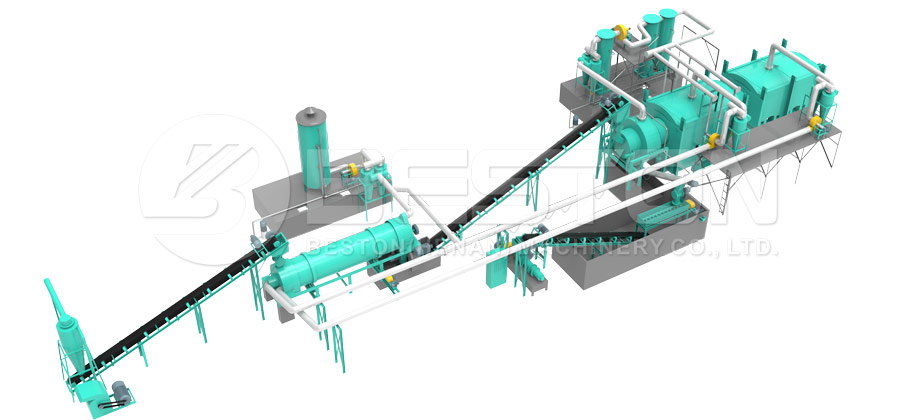

In the long run, it pays to research what charcoal kiln(planta de carbonización) for sale options are out there. Once you find what is a good price and a good kiln in general, you can spend money on it. Always look into this kind of thing so you don’t throw away good money on something that isn’t going to work for you.