Egg cartons are made in a very specific manner. It does require equipment to turn waste paper into pulp trays. If you have a large farm, and the production of your eggs is in excess of a million or more per month, you can get an egg tray production line to make your business more profitable. In both cases, the system by which the cartons are made is very similar. Here is what you should know about the egg carton manufacturing process and use this to your advantage.

How Are Egg Cartons Made

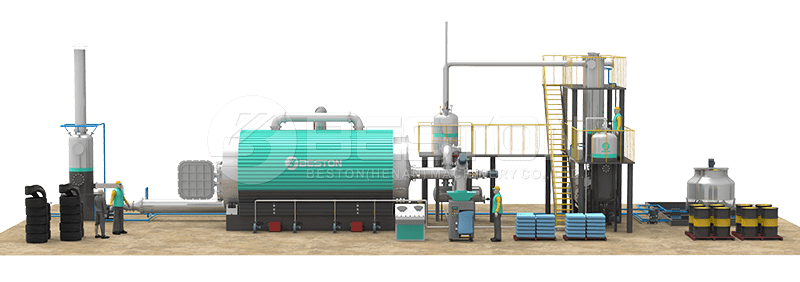

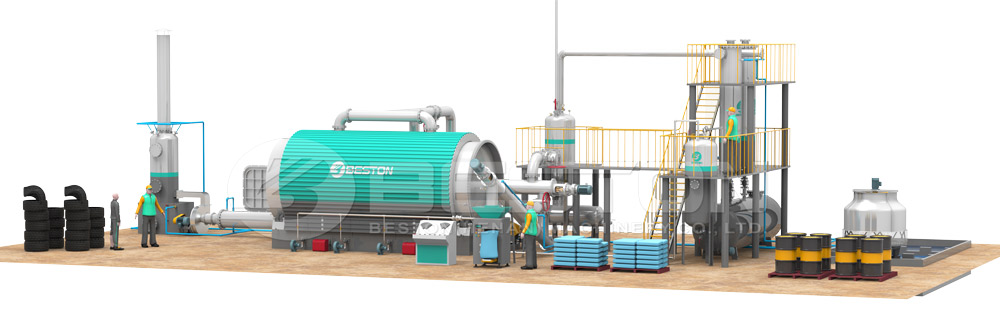

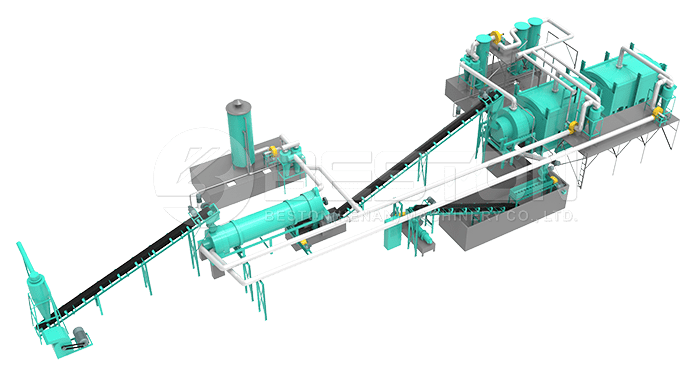

This process always begins with a type of pulp that is made into a liquid form. It is cleaned, processed, and made ready for pouring. It is then deposited into different trays that are going to be made in a wide variety of designs, such as 30-cavity egg trays, 6-shell egg cartons, etc. Once that is done, you can then begin to fill all of the molds that will be brought to be dried. There are brick and metal egg tray dryers to choose from, which means you can choose semi-automatic and fully automatic egg tray machine. Finally, the egg cartons are going to be taken out, stacked, and then used subsequently for processing the eggs. In no time, you are going to find several machines that will look appealing, as well as entire egg carton production plants that might be more of what you need.

Does The Process Remain The Same With Each Company?

The process itself is always going to be somewhat similar. It just depends on how many eggs you are producing, the number of cartons that you need, and how much space you have available. Not all of them are going to make them with the same configurations, however, they will certainly have similar components. Once you have assessed them based upon output price, you can then pay more close attention to the manufacturers themselves. Talk with representatives of the companies that can offer you special deals on certain ones that you may need to use at your facility.

How The Manufacturing Process Can Change

The egg carton manufacturing process itself is fairly straightforward. However, there are certain deviations in the plan depending upon their size. For example, there could be a number of conveyor belt system is installed that will deliver the egg cartons to different locations. Some of them are going to be stacked off whereas others will be used right away. There may also be two separate locations that are operating simultaneously. For larger systems, this will certainly be a possibility, and something you need to consider if you are limited in physical space where ever your business happens to be.

The egg carton manufacturing process is easy to understand. It is a basic way of producing cartons of any kind. Whether these are for physical products like shoes, or the eggs that you are producing every day, the entire manufacturing process will happen in a similar manner. If you do get something more expensive, you will likely have conveyor belt systems that will take up more space. Other than that, once you understand how the process occurs, you can assume it will function in that way once yours arrives at your place of business. More details: https://bestoneggtraymachine.com/egg-tray-manufacturing-business-plan/.