There are hundreds and, maybe even, thousands of brands. Once a particular design becomes successful, it doesn’t take long for copycats to copy the design and sell the same product under a different brand name. However, you can’t really be sure about the quality of materials and components used for making that copycat machine.

With so many brands out there, it is difficult for beginners to choose the right charcoal making machine(maquina para hacer carbon) as everything looks the same and without seeing one in action, the only thing a potential buyer may rely on is the price. Fortunately, there are a few things you can still consider differentiating between a good quality machine and a below – average machine. This blog post is focused on exploring the parameters that can help you choose the right machine for your charcoal production business. Here is what you need to know about choosing the right charcoal making machine:

Choose the Right Configuration for Your Purpose

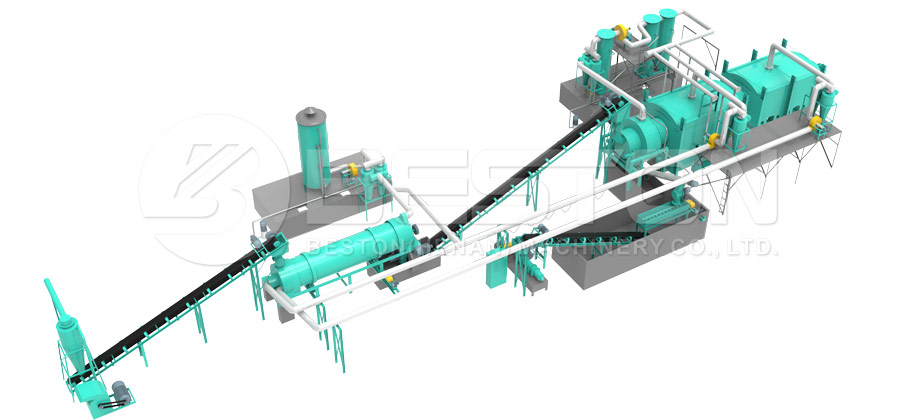

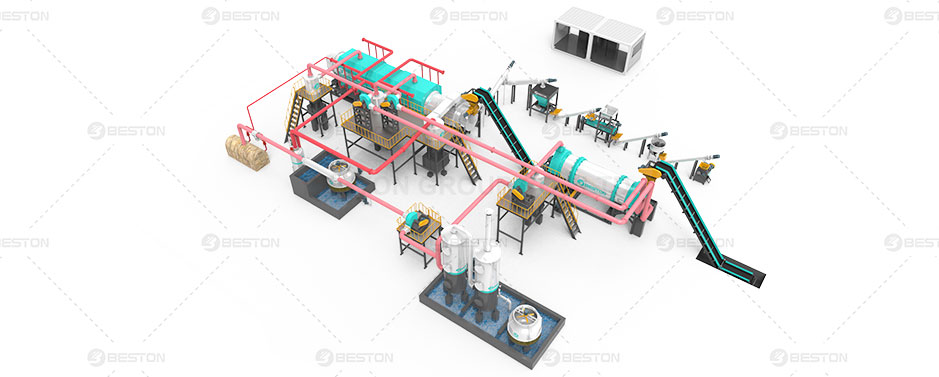

These machines are sold in both continuous and batch type configurations. A continuous type machine is best if you want to have a huge processing capacity and don’t need to change the specifications occasionally. A batch type machine is better for a situation where you need to consistently make changes to the processing specifications. In simple terms, the major difference between these two configurations is the processing capacity.

Choose a Processing Capacity

These machines(planta de carbonización) are sold in wide-ranging capacities. You can buy a machine with a capacity of a few hundred kilograms per hour, and there are also machines capable of processing a few tons of raw material at one time. Don’t think of buying as much capacity as you can afford to have, as buying too much capacity that is not properly utilized often leads to losses.

Choose the Level of Automation

These machines are sold with various levels of automation. There are fully automated production lines where operators don’t need to do much except push a few buttons. On the other hand, there are also semiautomated or manually operated machines with a low level of automation. Naturally, the price for the fully automated production line is much higher as compared to the alternatives. The choice ultimately depends on the scope of business. If you have a huge business, it makes sense to invest in a fully automated line, as it will allow you to increase production immensely.

Compare Prices

Everybody compares prices. However, most people restrict their search to only the local suppliers when comparing prices. You should know that it is better to ask for estimates from at least a few different foreign suppliers(máquina de reciclaje) in addition to local suppliers. It will allow you to get better rates. If you plan to go with a foreign supplier, always make sure they have a local service office.

Customer Reviews

Just like you check reviews before buying a home appliance, it is important to check reviews before buying a charcoal making machine. You probably won’t find the reviews that easily, but once you join a few online communities related to the industry, it won’t be that difficult.

Final Thoughts

Overall, there is a huge variety of charcoal making machines available in the market at various price points. It is important for you to pay attention to the level of automation, the reputation of the manufacturer, customer reviews and configuration of the machine(https://www.bestoneco.com/hornos-metalicos-para-hacer-carbon/) to make the right choice and to set up an excellent foundation for your business.