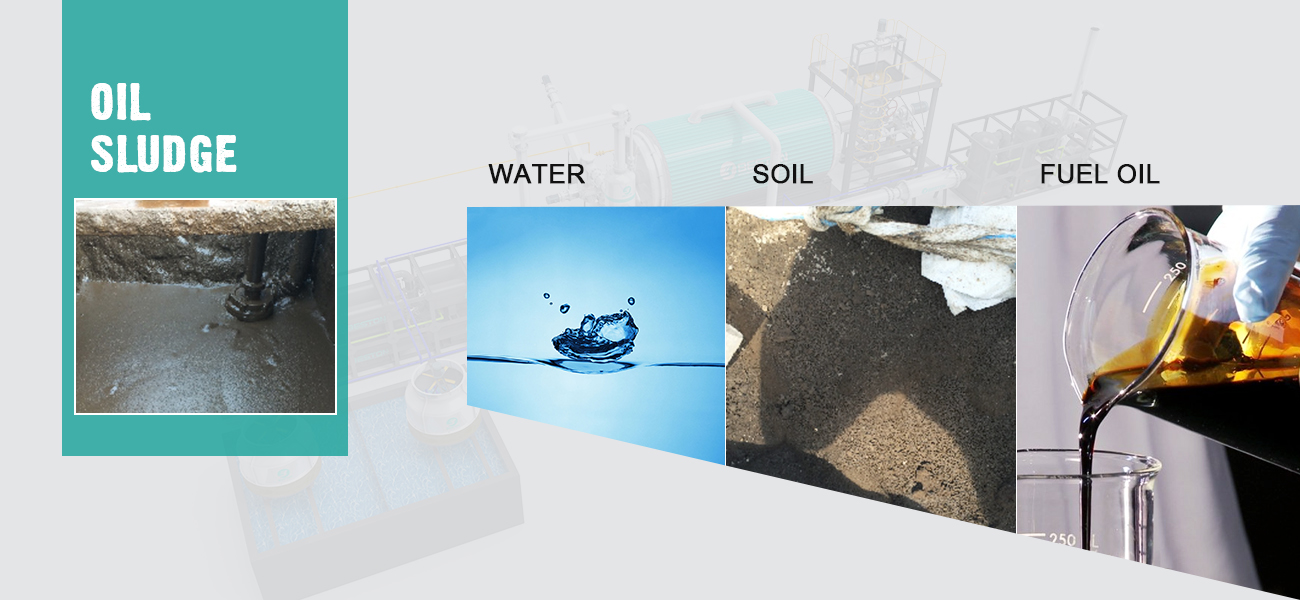

In the intricate realm of waste management, one of the paramount challenges faced by the oil industry is the handling and disposal of oil sludge. This complex mixture of oil, water, and solid particles emerges as a byproduct during various stages of oil extraction, refining, and transportation. Its composition deems it hazardous, necessitating a sophisticated approach for treatment and disposal.

Understanding the Enigma: What is Oil Sludge Treatment?

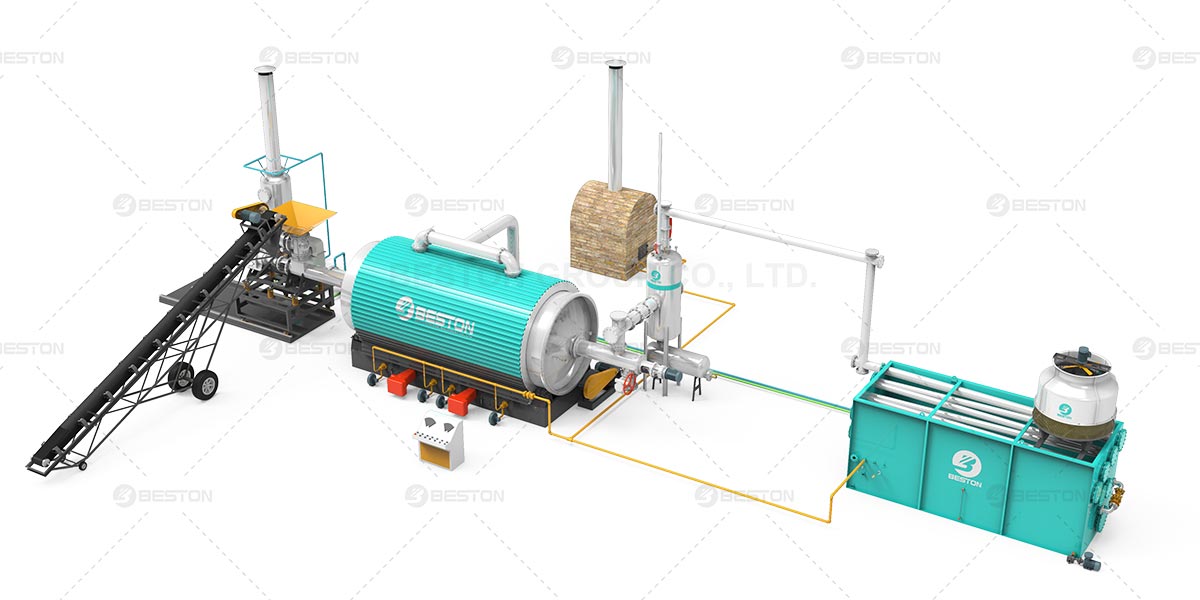

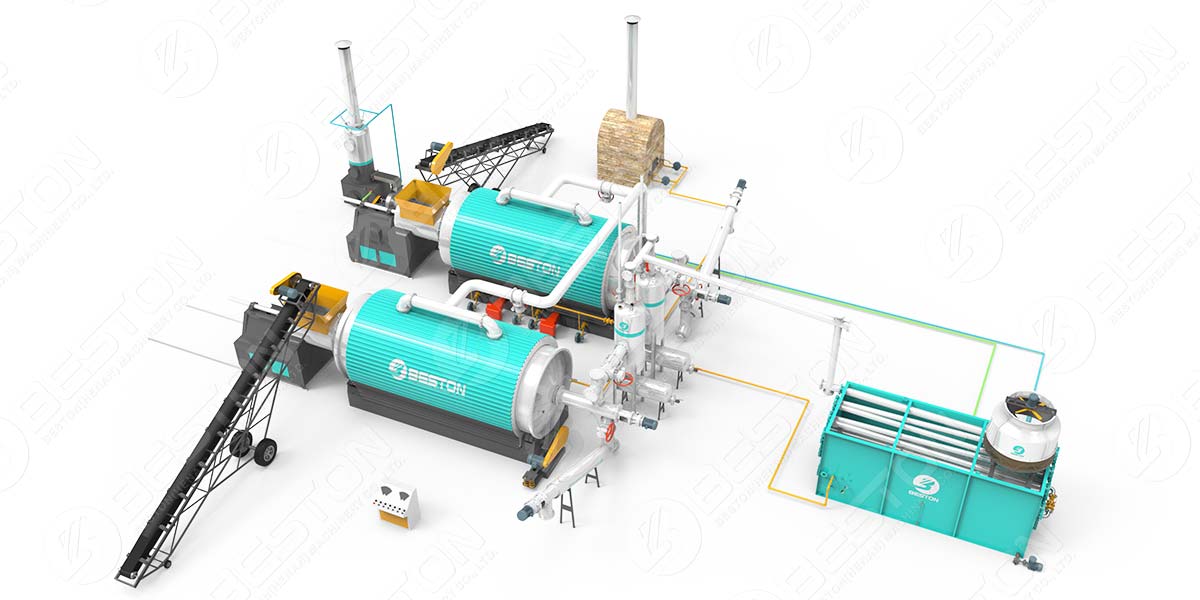

Oil sludge treatment is a revolutionary process that transcends conventional waste management methodologies. At its core lies the principle of pyrolysis, a thermal treatment method involving the application of heat in the absence of oxygen. This transformative process orchestrates the breakdown of organic compounds within the oil sludge, yielding gases and a solid residue. More information on oil sludge pyrolysis plant here.

The Dance of Elements: Steps in Oil Sludge Pyrolysis

- Feedstock Preparation: Commencing the journey, oil sludge undergoes meticulous preparation, ensuring optimal conditions for the subsequent pyrolysis process.

- Pyrolysis Reactor: The prepared oil sludge takes center stage in the pyrolysis reactor, where the absence of oxygen triggers a mesmerizing thermal dance, unraveling the intricacies of its composition.

- Gas and Oil Recovery: From the mystique of pyrolysis emerge valuable byproducts—gases and oil. These treasures can be harnessed for diverse purposes, from energy generation to refined applications.

- Solid Residue Treatment: The pyrolysis spectacle leaves behind a solid residue akin to carbon black. This residue, though seemingly inert, may hold untapped potential or necessitate further refinement before its ultimate disposition.

- Emission Control: Environmental stewardship takes precedence as the process unfolds. Rigorous measures are in place to control emissions, ensuring compliance with stringent environmental regulations.

Decoding the Lexicon: Keywords at the Forefront

- Oil Sludge Treatment

- Pyrolysis

- Feedstock Preparation

- Gas and Oil Recovery

- Solid Residue Treatment

- Emission Control

Delving Deeper: A Glimpse into Pyrolysis

The Alchemy of Pyrolysis

In the alchemical crucible of pyrolysis, oil sludge undergoes metamorphosis. The absence of oxygen sets the stage for the disintegration of organic compounds, a molecular ballet that begets gases and oil. This not only transforms waste into a resource but also exemplifies sustainable waste management—an imperative in the contemporary environmental landscape. Check the thermal desorption unit here.

Precision in Feedstock Preparation

Before the grandeur of pyrolysis unfolds, a meticulous ballet of preparation takes place. Feedstock preparation involves the careful curation of oil sludge, optimizing its composition for the impending thermal spectacle. This precision ensures the efficiency and effectiveness of the subsequent stages.

Harnessing Wealth from Waste: Gas and Oil Recovery

As pyrolysis performs its symphony, the stage is graced with the emergence of two valuable protagonists—gases and oil. These entities, once considered waste, now step into the spotlight as potential energy sources or candidates for refined applications. Gas and oil recovery transforms the narrative, aligning waste management with resource optimization.

The Residue Riddle: Solid Residue Treatment

In the aftermath of pyrolysis, a residue akin to carbon black stands as a testament to the process. This solid residue may hold latent value or demand further attention before its conclusive fate is sealed. Solid residue treatment involves deciphering the residue riddle—unveiling its potential or preparing it for a responsible exit from the waste management narrative. Find the pyrolysis plant for sale here.

Guardian of the Environment: Emission Control

Environmental stewardship is woven into the fabric of oil sludge treatment. As the process unfolds, stringent measures are in place to curtail emissions, ensuring that the environmental impact remains within the bounds of regulatory compliance. Emission control emerges as the guardian, preserving the delicate balance between technological advancement and ecological responsibility.

Navigating the Future: Towards Sustainable Waste Management

In the labyrinth of waste management challenges, oil sludge treatment stands as a beacon of innovation. The amalgamation of pyrolysis, precise feedstock preparation, resourceful gas and oil recovery, strategic solid residue treatment, and vigilant emission control charts a course towards sustainable waste management practices.

As industries evolve and environmental consciousness deepens, the journey of oil sludge treatment becomes more than a technological marvel; it becomes a testament to the symbiosis between progress and responsibility. Through the lens of pyrolysis, oil sludge transcends its status as mere waste, metamorphosing into a resource with the potential to redefine the landscape of waste management. Visit the Beston Group to get more information.