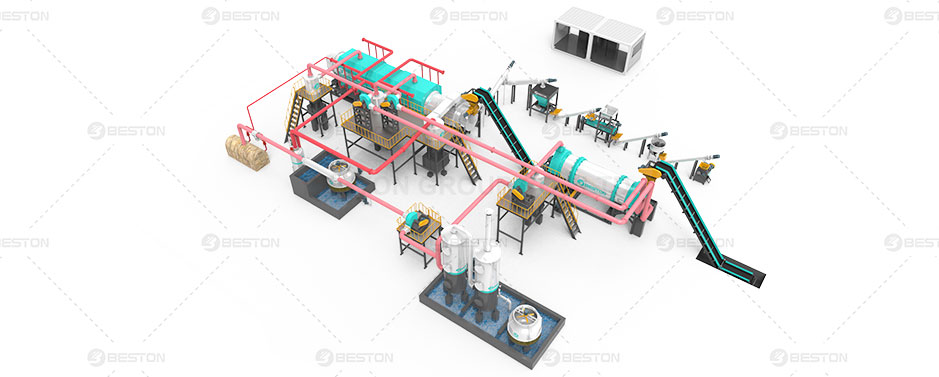

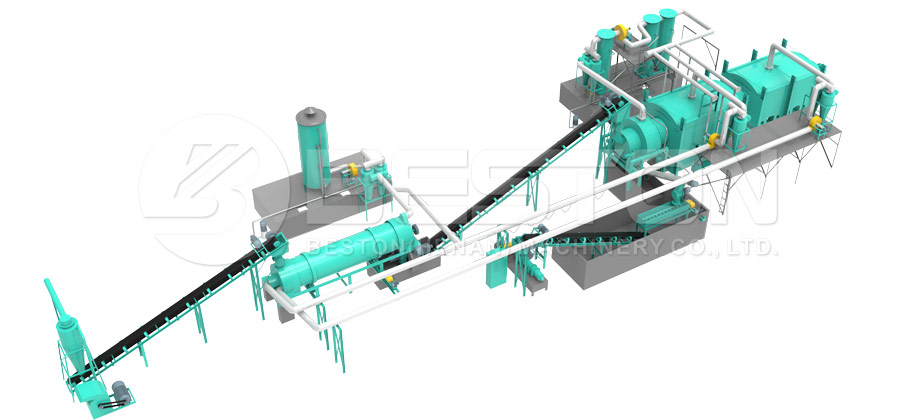

Biochar and charcoal production systems are becoming strategic components in regional carbon offset frameworks as governments and industries seek durable, verifiable methods for long-term carbon sequestration. Technologies such as biochar production equipment, a wood pyrolysis plant, systems for making charcoal from sawdust, and a coconut shell charcoal making machine now enable precise control over carbonization parameters, ensuring both environmental performance and commercial viability. Their integration into carbon offset programs reflects a broader shift toward decentralized, biomass-centered carbon management.

Strengthening Carbon Sequestration Through Stable Carbon Forms

Biochar offers exceptional permanence as a carbon sink. Its aromatic molecular structure resists microbial degradation, allowing carbon to remain locked in soils for centuries. Regional carbon offset programs incorporate biochar because it converts short-cycle biomass carbon into long-cycle stable carbon, reducing atmospheric CO₂ concentration. When produced using efficient biochar production equipment, the resulting material meets quality thresholds for carbon permanence, surface area, and mineral content, improving both sequestration metrics and agricultural functionality.

Leveraging Diverse Biomass Streams for Localized Carbon Strategies

The versatility of modern pyrolysis systems enables regions to utilize abundant local residues. A wood pyrolysis plant transforms forestry by-products into carbon-rich solids while simultaneously generating recoverable thermal energy. Processes for making charcoal from sawdust convert fine particulate residues into stable carbon materials suitable for soil applications or fuel markets. A coconut shell charcoal making machine provides a pathway for tropical regions to monetize agricultural waste, aligning carbon reduction goals with economic development. This feedstock flexibility allows governments to design carbon offset programs tailored to regional biomass availability and industrial capacity.

Enhancing Program Credibility Through High-Precision Pyrolysis

For carbon offset credits to be legitimate, carbonization systems must meet strict monitoring and verification standards. Modern pyrolysis plants incorporate automated control modules, continuous temperature logging, and syngas recirculation data that support rigorous reporting protocols. These features ensure reproducible carbon yield calculations, reduced emissions, and quantifiable carbon retention levels. High-efficiency systems minimize methane slip and tar emissions, strengthening the environmental integrity of carbon offset credits.

Co-Benefits for Agriculture and Land Restoration

Beyond carbon sequestration, biochar delivers critical agronomic advantages. Its high porosity enhances soil moisture retention, nutrient buffering, and microbial habitat formation. Regions suffering from soil degradation integrate biochar into land-restoration initiatives to rebuild fertility. When applied at scale using material derived from wood pyrolysis plant operations or coconut shell charcoal making machine outputs, biochar supports improved crop productivity and reduces fertilizer dependence. These co-benefits allow regional carbon programs to claim broader ecological value.

Economic Viability Through Multi-Output Valorization

Pyrolysis systems generate additional revenue streams that improve project economics. Syngas can be reused internally for heating, reducing operational costs. Condensable oil fractions serve as industrial heating fuels or chemical feedstock. Charcoal produced from systems designed for making charcoal from sawdust or coconut shells supports local markets in metallurgy, cooking fuel, and filtration. This multi-output structure enhances financial resilience, enabling carbon offset projects to remain profitable even in volatile carbon-credit markets.

If you need a version aligned with a specific region’s carbon policies or certification standards, it can be developed.